Welcome to Hampshire Woodturners Association

Perhaps you have just discovered woodturning and want support and advice as you explore this fun and creative new hobby?

Or perhaps you are already a keen woodturner and are interested in improving your woodturning skills?

Whether you are a beginner or an advanced turner, or anything in between, Hampshire Woodturners Association can help you grow. You’ll meet an enthusiastic and friendly group who will welcome you with help and inspiration, whatever your current skill level.

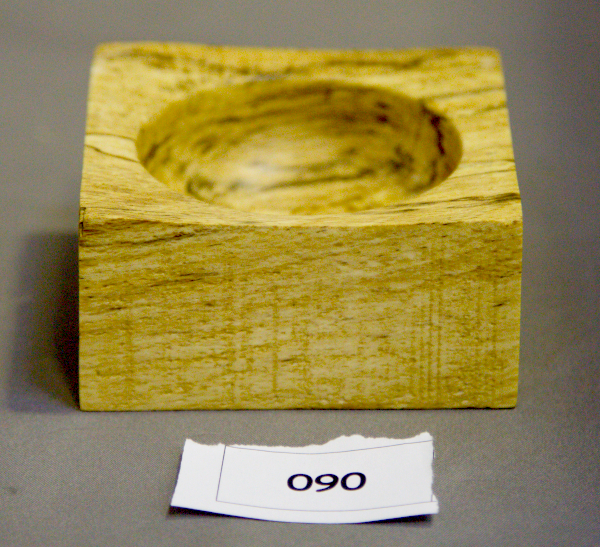

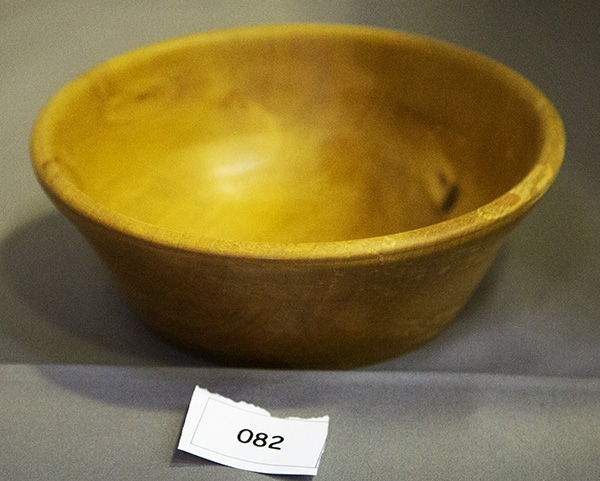

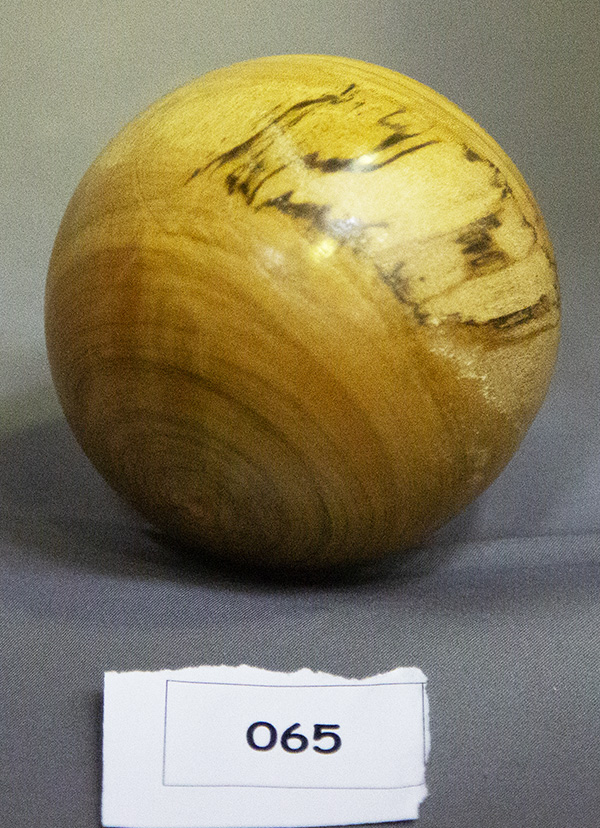

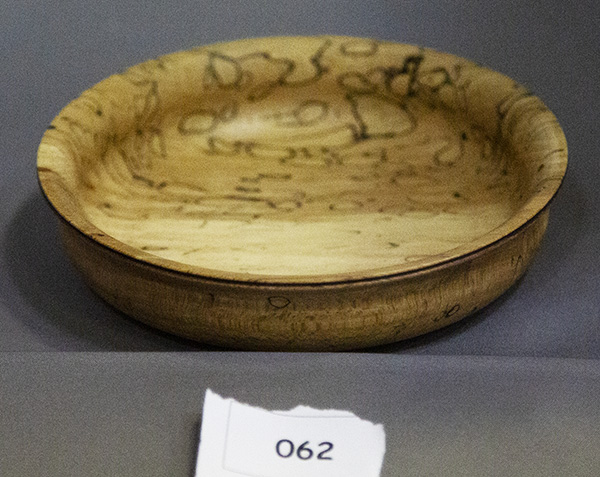

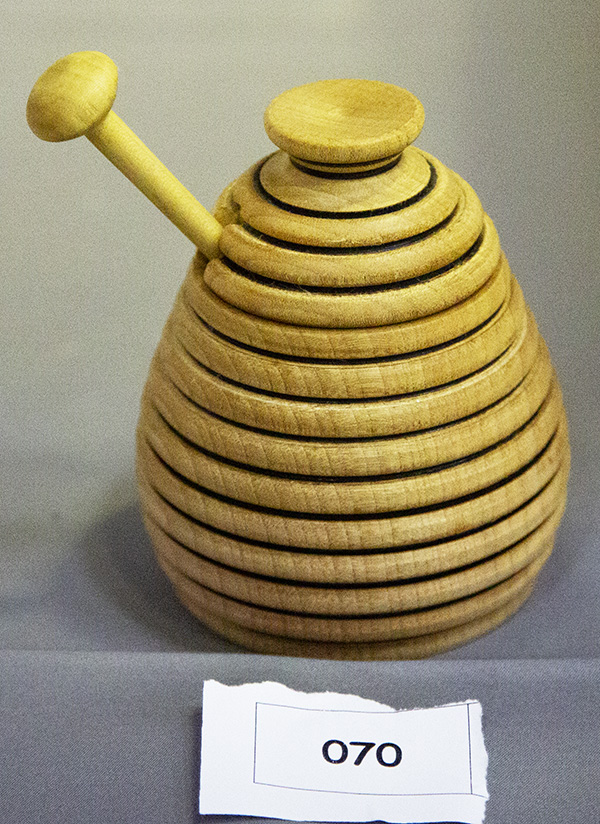

We have an interesting and varied monthly programme with plenty of members to encourage and support you whatever your level of expertise. There is always something new to learn, someone new to meet, and the chance to see what our members have been turning. See the Gallery posts below for examples of the creations that members have been bringing to the meetings.

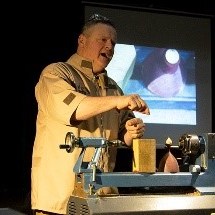

Many of our meetings feature demonstrations from professional turners, while sometimes our club lathes are set up and all have the opportunity to participate. There is also usually a well-stocked raffle and refreshments.

See the About Us section to find out more details of who to contact, where to find us and so on.

Our Event Calendar page will give you details of what is happening in our monthly meetings, and also gives details of additional events that are arranged during the year. We are also always happy to welcome visitors to the club for our meetings.

We hope to see you soon!